Customer challenge

Customer: ASML

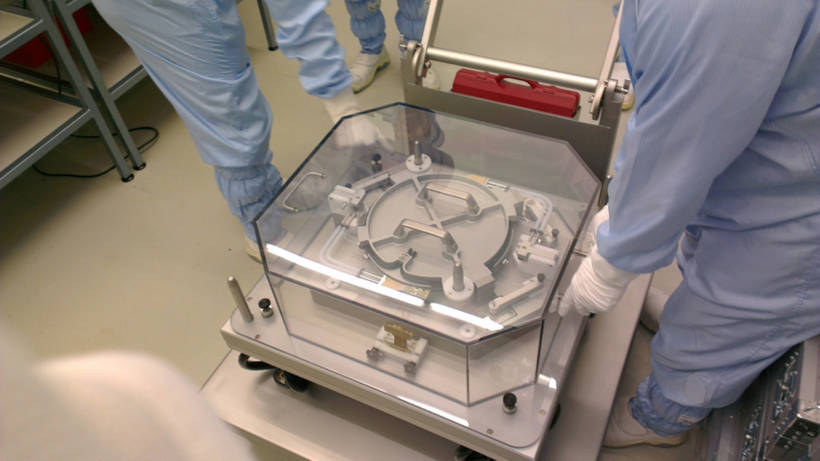

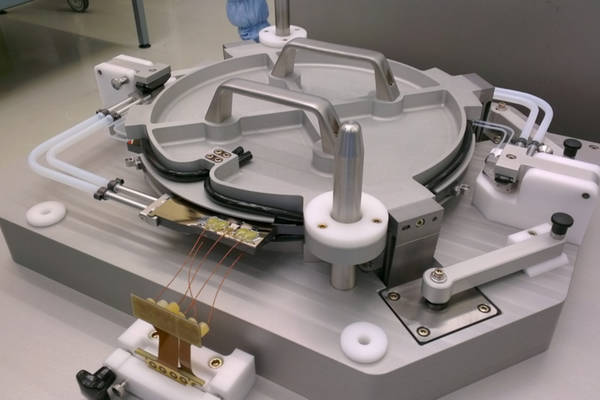

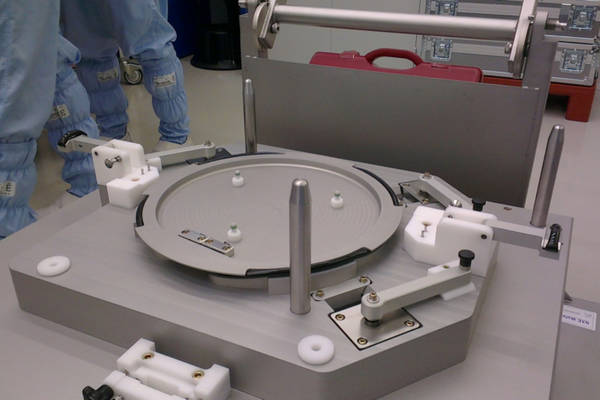

Enable transport of wafer clamping module from supplier to ASML and from ASML to customer.

The product is made of ceramic with nanometer flatness and surfaces that are only tenths of millimeters thick. The applied surface stress must therefore very low. The particles that the transport tool was allowed to add was close to nothing.

As the product is very fragile, the incoming shocks and vibrations need to be lowered to an acceptable level of max 7G (70 m/s^2). Climatical influences needed to be controlled as well. The temperature range was set to 0 – 45°C.